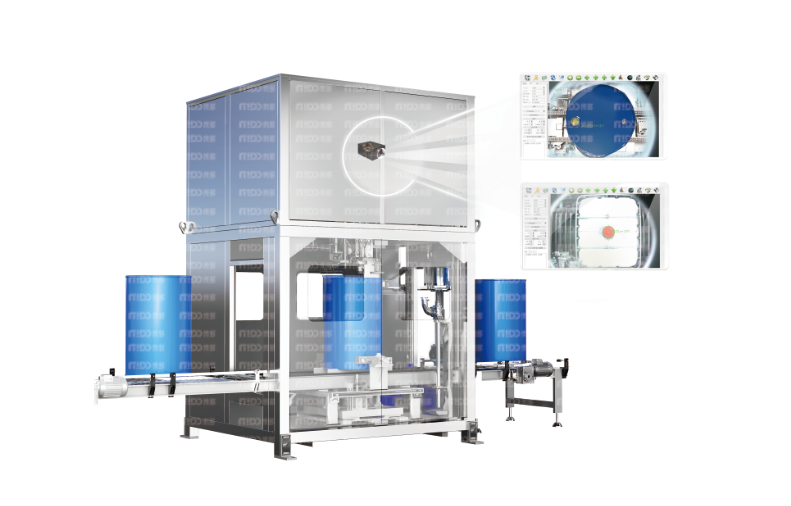

▼产品说明:

本机针对防爆环境内的包装而设计的智能化包装系统。本灌装机工位组成,自动移门、自动寻口定位、自动开盖、自动灌装、自动充氮、自动封盖、自动防水盖紧盖。在灌装间前后设有自动阻隔门。灌装系统设在灌装房内,外接业主VOC排风管道使其处于微负压状态,避免废气外逸。灌装机设置2套独立结构的物料灌装枪头系统,一用一备,可根据指令启动其中一套灌装枪灌装,从而实现了全自动独立灌装的功能。采用视觉系统定位,控制系统根据桶口位置参数通过伺服移动系统使指定灌装枪精确逐个到达桶口位置,自动完成开盖、灌装、充氮、旋盖不同的物料均使用各自独立的灌装系统,避免交叉污染。灌装机设有接漏设计,保证在灌装完成换桶过程中,物料不会滴落在桶外。

▼Describe:

This machine is an intelligent packaging system specially designed for packaging in explosion-proof environments. The filling machine station is composed of automatic sliding door, automatic seeking drum mouth and positioning, automatic opening cap, automatic filling, automatic nitrogen filling, automatic capping, automatic waterproof cap tightening. Automatic barrier doors are available at the front and rear of the filling room. The filling system is located in the filling room, and the external owner's VOC exhaust pipe makes it in a state of micro-negative pressure to avoid the escape of exhaust gas. The filling machine is equipped with 2 sets of independent structure material filling nozzle system, one use and one backup, and any set of filling nozzle filling can be started according to the instructions, so as to realize the function of fully automatic independent filling. Using visual system positioning, the control system makes the specified filling nozzle accurately reach the position of the drum mouth one by one through the servo mobile system according to the position parameters of the drum mouth, and automatically completes the opening cap, filling, nitrogen filling, and capping of different materials using their own independent filling systems to eliminate cross-contamination.The filling machine is equipped with a leakage tray design to ensure that the material will not drip outside the drum during the filling process.

☉ 视觉相机自动识别定位,精准灌装 |  |

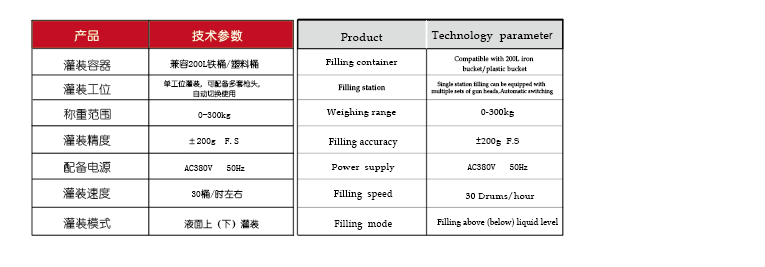

▼技术参数:Product Details

|

截屏,微信识别二维码